Introduction: The Rise of the Tortellinatrice in Modern Cuisine

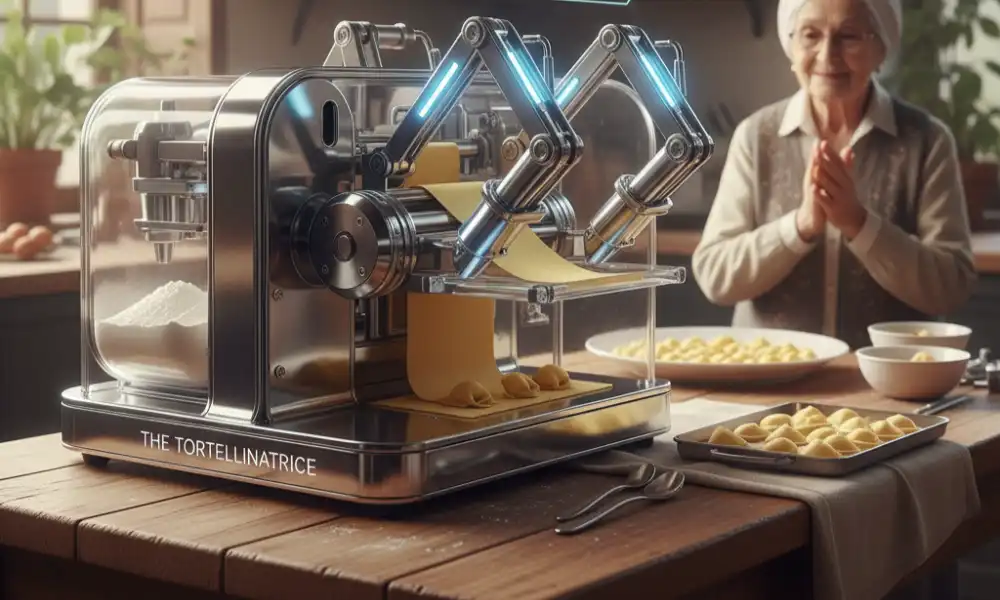

In the world of Italian cuisine, few dishes capture the essence of craftsmanship and tradition quite like tortellini. These tiny, ring-shaped pasta pieces — delicately folded around a savory filling — are symbols of culinary precision and cultural pride. Traditionally, making tortellini by hand required exceptional skill, patience, and time. However, the introduction of the Tortellinatrice, a specialized pasta-making machine, has transformed this centuries-old art into a modern, efficient process without sacrificing authenticity.

The Tortellinatrice bridges the gap between handcraft and technology. It ensures that the texture, taste, and appearance of tortellini remain faithful to the handmade version, while allowing large-scale production for restaurants and food manufacturers. Let’s explore how this fascinating machine works, its history, advantages, and the impact it has made on the global pasta industry.

1. What Is a Tortellinatrice? Understanding Its Function and Design

The term “Tortellinatrice” originates from the Italian word tortellini (the pasta) and -trice (a suffix denoting a machine or tool that performs an action). In essence, it means “tortellini-making machine.”

Unlike ordinary pasta cutters or extruders, the Tortellinatrice is specifically engineered to fold, fill, and seal tortellini with exceptional precision. Its design mimics the delicate motion of human hands — rolling, wrapping, and pressing the dough just enough to hold the filling without tearing.

Key features of the Tortellinatrice include:

- Filling dispenser: Injects the perfect amount of filling (meat, cheese, or vegetables) into each pasta pocket.

- Molding system: Shapes the dough around the filling to achieve the signature “belly-button” tortellini form.

- Sealing mechanism: Uses gentle pressure to seal the edges tightly, ensuring no leakage during cooking.

- Adjustable settings: Allows customization for different sizes, dough thickness, and filling density.

The result? Consistently perfect tortellini that maintains the flavor and artistry of traditional craftsmanship, but at a speed suitable for modern production.

2. The Evolution of Tortellini Making: From Handcraft to Mechanization

To appreciate the significance of the Tortellinatrice, it’s essential to understand where it began. Tortellini originates from Emilia-Romagna, a region in northern Italy celebrated for its rich culinary history. Local legends claim that the pasta’s shape was inspired by the belly button of Venus, symbolizing beauty and passion in food.

For generations, tortellini were made entirely by hand — a process that demanded both skill and time. Dough was rolled thin, cut into small squares, filled with a mixture of meats or cheeses, and then carefully folded and sealed. Each piece was a work of art.

As the popularity of Italian cuisine spread worldwide, the demand for authentic tortellini increased dramatically. This led to the invention of the Tortellinatrice, allowing pasta makers to produce large quantities without compromising quality. The machine became a bridge between tradition and technology — keeping the spirit of Italian cooking alive in an industrial world.

3. How the Tortellinatrice Works: A Step-by-Step Process

The operation of the Tortellinatrice is both mechanical and artistic. While modern machines rely on automation, their internal process mirrors that of skilled artisans.

Here’s how a typical Tortellinatrice functions:

- Dough Preparation: Fresh pasta dough is prepared using flour and eggs, then fed into the machine in thin sheets.

- Filling Distribution: A built-in filling injector dispenses the exact amount of filling onto the pasta sheet at regular intervals.

- Folding and Molding: The machine folds the dough over the filling and presses it into the traditional tortellini shape.

- Sealing: A soft press ensures that the edges are sealed without breaking the dough’s texture.

- Cutting and Output: The finished tortellini are cut, separated, and ready for packaging, freezing, or immediate cooking.

Some high-end models of the Tortellinatrice can even simulate the hand-folding motion, producing pasta that is almost indistinguishable from handmade versions. This technological innovation ensures that taste, texture, and appearance remain consistent with Italian culinary standards.

4. Advantages of Using the Tortellinatrice

The Tortellinatrice is more than a piece of machinery — it’s a game-changer for chefs, restaurants, and food manufacturers. Here are some of its most important advantages:

a. Efficiency and Speed

Manual tortellini-making can take hours, but with a Tortellinatrice, hundreds of pieces can be created in minutes. This efficiency allows kitchens to meet high demand while maintaining quality.

b. Consistency in Quality

Each tortellini is identical in shape, size, and filling ratio. Consistency is essential for commercial production, ensuring customers experience the same quality every time.

c. Preservation of Traditional Flavor

Despite being machine-made, the Tortellinatrice is designed to imitate the traditional folding technique, keeping the authentic taste and texture intact.

d. Customization and Versatility

Modern machines allow for adjustments in filling types, pasta thickness, and shape. From classic tortellini di carne (meat-filled) to vegetarian ricotta versions, the possibilities are endless.

e. Economic Advantage

By reducing manual labor costs and waste, the Tortellinatrice offers long-term savings for businesses without compromising craftsmanship.

5. The Tortellinatrice in the Global Culinary Market

As global demand for authentic Italian cuisine continues to grow, the Tortellinatrice has found its place in both small artisan shops and large-scale pasta factories. In Italy, it is seen as a respectful innovation — a way to preserve tradition while embracing modernization.

In countries like the United States, Japan, and Canada, many gourmet food producers have adopted the machine to offer fresh, handmade-quality tortellini to consumers who crave authenticity but value convenience.

The Tortellinatrice also plays a significant role in culinary education. Cooking schools use it to teach students how pasta is shaped, filled, and sealed — blending traditional techniques with modern machinery.

This balance between heritage and innovation has made the Tortellinatrice not only a symbol of Italian ingenuity but also a global standard for quality pasta production.

6. Future Innovations: Smart Tortellinatrici and Sustainability

As technology advances, new versions of the Tortellinatrice are being developed with AI-driven automation, precision sensors, and sustainable materials. These machines can detect filling pressure, adjust sealing temperatures, and even alert users about maintenance requirements.

Moreover, eco-friendly versions are being designed to reduce energy consumption and food waste, aligning with the growing sustainability goals of the food industry.

The next generation of Tortellinatrici will not only enhance efficiency but also support environmentally conscious production — ensuring that Italian culinary traditions thrive in a sustainable future.

Conclusion: The Perfect Blend of Tradition and Technology

The Tortellinatrice stands as a perfect example of how innovation can preserve tradition rather than replace it. It captures the soul of handmade tortellini — the care, the detail, the artistry — and translates it into a modern culinary process that reaches people around the world.

Through precision engineering and respect for heritage, the Tortellinatrice ensures that the taste of Italy remains timeless. Whether in a small trattoria or a large factory, every bite of tortellini made with this machine tells a story — one of love, craftsmanship, and evolution in the world of pasta.

Check Out Other related articles

- Lidarmos: The Light-Powered Revolution Transforming Modern Mapping and Perception

- Gaymetu e: The Rise of a Digital Identity in the Age of Online Expression

- Närkes Elektriska: Powering the Future with Innovation and Sustainability

- Kingxomiz: The Cultural Revolution Redefining Modern Expression

- Blazertje: The Subtle Fashion Statement Taking Over Modern Wardrobes